What is pre-engineered steel building?

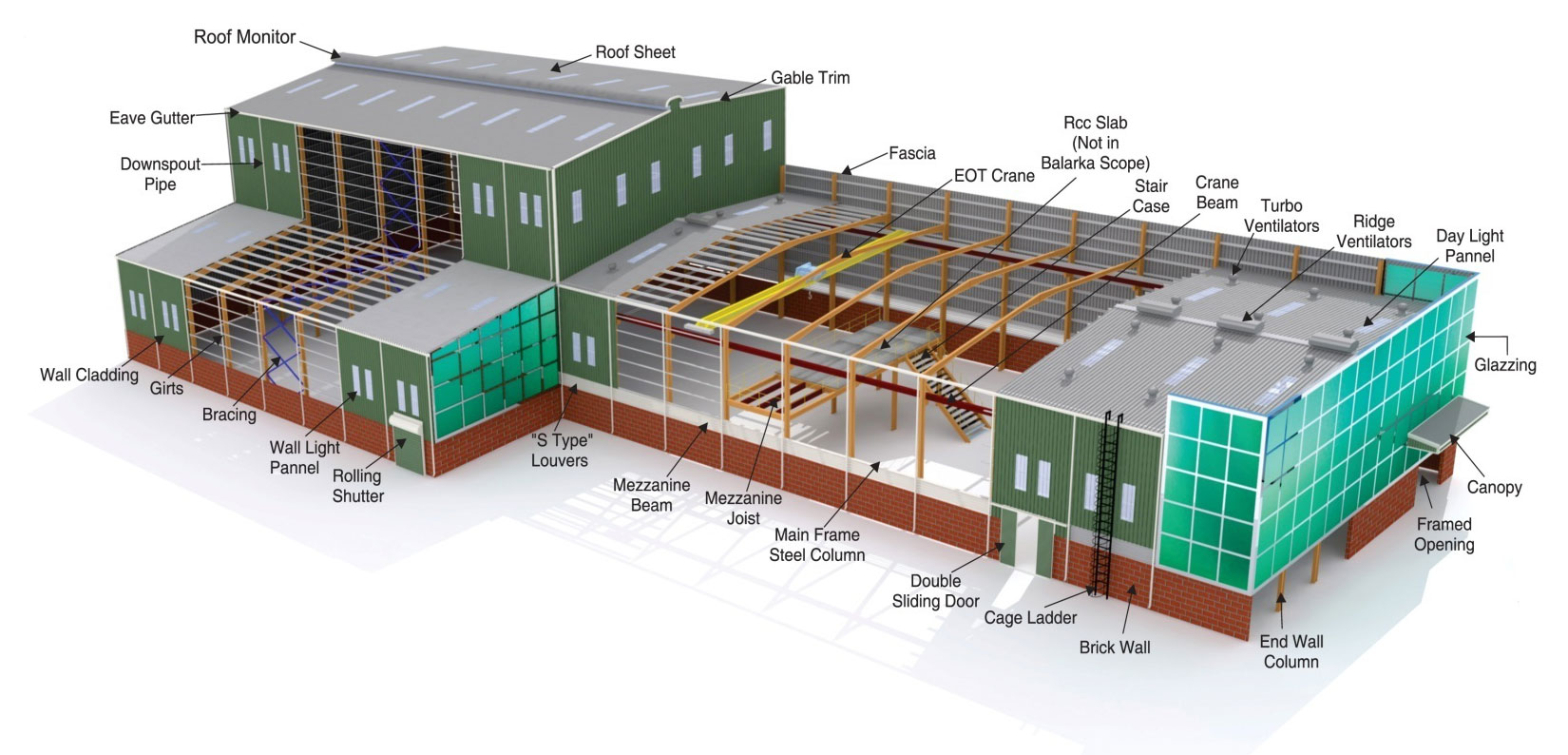

- Primary framing component: Main framing basically includes the rigid steel frame of the building (columns and rafters). The building’s major load is being borned by these members. They are usually made of built-up beams with a cross-section “I” or “H”.

- Secondary components: Purlins, Girts and Eave struts are secondary structural members used as support to walls and roof panels. Purlins and girts shall be cold-formed “Z” sections or “C” sections with stiffened flanges.

- Sheeting or Cladding for roof and wall. The sheeting materials are usually cold-rolled steel, high tensile 550 MPA yield stress, with hot dip metallic coating of galvalume sheet or anti-rust painting.

Besides the main components, the pre-engineered steel building also has a number of accessories to complete the project:

-

Insulations

-

Canopy, roof skylight, door and window

-

Trim and flashing system, gutters, ridge ventilators..

-

Overhead crane system…

The basic parameters of a pre-engineered steel building

-

Building Width: is defined as the distance from outside of eave strut of one sidewall to

-

outside of eave strut of the opposite sidewall

-

End Bay Length: This is the distance from outside of the endwall columns’ outer flange to the centerline of the first interior frame columns.

-

Building height:Building height is the eave height which usually is the distance from the bottom of the main frame column base plate to the top outer point of the eave strut

-

Interior Bay Length: This is the distance between the center lines of two adjacent interior main frame columns. The most common bay lengths are 6m, 7.5m and 9m. Any bay length up to 15m is possible

-

Roof Slope (x/10): This is the tangent of the roof with respect to the horizontal. The most common roof slopes are 0.5/10 and 1/10. Any practical roof slope is possible

-

Dead Load: The self weight of the pre-engineered building structure including all its components such as frames, floors, secondary members, sheeting, bolts, etc.

-

Live load: Any variable load that results from intended use of the structure during its lifetime.

Advantages of pre-engineered steel buildings

Optimal cost, Competitive price

The price per square meter can be 20-30 % lower when compared to the conventional building construction. To reach this impressive number, each stage of the pre-engineered steel building is optimized by:

-

Designed with modern technical standards to help optimize the amount of materials used and use renewable or recycled source materials.

-

Factory manufacturing under strict quality control system helps to minimize errors and defective products

-

Simple and fast erection at the site helps shorten construction time and save erection costs

High quality, Long lifetime

Pre-engineered steel building components are designed and manufactured at the factory before being installed on site. Input materials are selected from reputable suppliers with clear origins. Besides, the steel components will go through the quality control process before delivering to the site. Modern and professional pre-engineered steel building factories apply international standards in our operation and manufacturing processes such as:

-

ISO quality management system

-

OHSAS Occupational Health and Safety Management System standard.

Tailor-made building solution to the investor’s architectural and business requirements

Another advantage of pre-engineered steel buildings is that they are customized steel buildings to adapt the specific needs for every company. Depending on the industry, production line, geographic location, and investment capital of the investor, each project will be consulted and designed accordingly. PEB companies with a team of specialized and experienced engineers will provide the optimal solution for customers.

Easy expansion, efficient recycling

Manufacturing factories often have plans to expand in the future. Therefore, pre-engineered steel buildings are the perfect choice because they are flexible to expand their area at a very low cost. Not only that, the space in pre-engineered steel buildings is also easy to change depending on the needs of users. At the end of the project’s lifespan, companies can get a portion of their investment capital back by recycling steel.

Eco friendly buildings

As a 70% popular industrial building worldwide, pre-engineered steel buildings are increasingly being used for its environmental friendliness. Combined with the application of green building standards, pre-engineered steel buildings help reduce CO2 emissions, save energy, and efficiently recycle.

BAO DUNG STEEL – ALWAYS DEDICATED TO CUSTOMERS’ SUCCESS

For further information, please contact:

BAO DUNG MECHANICAL CONSTRUCTION COMPANY LIMITED

- No. 149 CN11 Street, Son Ky Ward, Tan Phu District, Ho Chi Minh City, Vietnam

- Hotline: 0903 830 857

- Email: cokhixaydungbaodung@gmail.com

- Website: baodungsteel.com