BAO DUNG Steel Structure provides a full-service pre-engineered steel building solution to our customers. We offer a wide range of metal sheeting (metal panels) for a variety of roof, wall & soffit applications in particular. All metal sheeting is fabricated at Long An factory with high-quality and on time progress. Our modern metal sheeting products are applied with the latest technology and suitable for all types of weather.

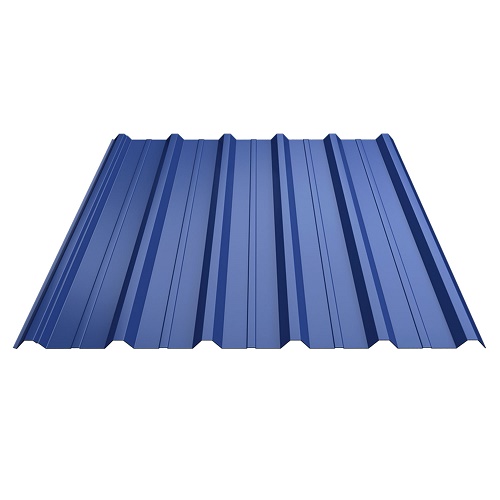

5 rib steel panel

This is one of the most original and common types of roofing sheets. The panel is designed with 5 high ribs so it has good drainage performance. In addition, the panel length is flexible according to the requirements of the project.

Feature

5 rib steel panel (box ribs) is formed at VIS factory from high-quality cold-coated, galvanized or colored coated steel sheet. We apply Japanese JIS or American ASTM technical standards in the manufacturing process

The male-rib height of 32 mm in accordance with international standards, wide rib distance with a distance of 250mm

Use self-drilling screws for joining roof panels to purlins

Advantages

5 rib steel panel is manufactured from materials with a clear origin. It is strong, durable, and has flexible length according to customer requirements.

5 rib steel panel has high ribs, wide rib distance so it has good drainage performance and can prevent water overflow for factories with wide spans and low roof slopes. In addition, the wide rib distance makes it easy to erect and maintain periodically without fear of panel deformation.

Application

5 rib steel panel is one of the most popular types of roofing. It is designed to be used for roofs and walls of factories, warehouses, showrooms, trade centers …

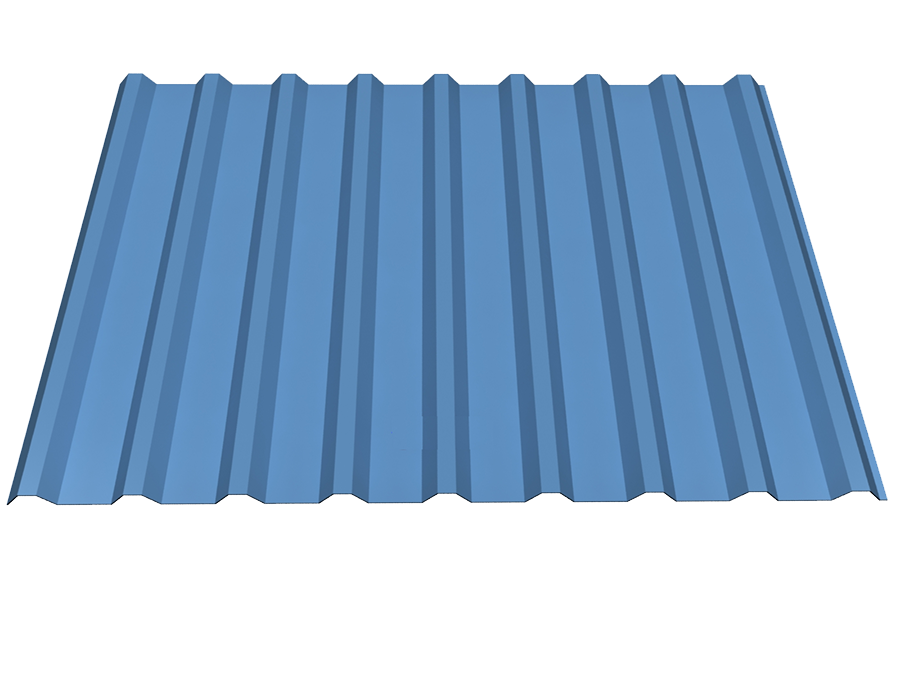

9 rib steel panel

Due to the low ribs and narrow rib distance, 9 rib steel panel is often used as a wall panel (cladding) to replace conventional 5 rib steel panel.

Feature

9 rib steel panel is formed at Bao Dung factory from high-strength cold-coated, galvanized or colored coated steel sheet (G550 or G350). We apply Japanese JIS or American ASTM technical standards in the manufacturing process

The male-rib height of 21 mm in accordance with international standards, rib distance of 125mm. Use self-drilling screws for joining roof panels to purlins

Advantages

9 rib steel panel is able to withstand wind with a Beaufort wind force of 8 – 12 because the system provides a combination of a strong joint.

The low ribs and the narrow rib distance creates architectural aesthetics for civil and industrial projects.

Application

Thanks to its high aesthetics, 9 rib steel panel is used to make interior partitions, ceiling panels, cladding, walls for various kinds of building

On the other hand, 9 rib steel panel is rarely used in roofing for industrial factories, especially in the tropical climate (including Vietnam). Because of the low ribs and the narrow rib distance, the drainage capacity is not as good as other types of panels.

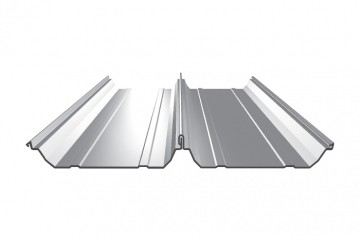

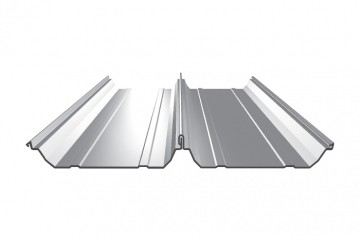

LokSeam 470 panel

LokSeam 470 steel panel is one of the most recommended roofing systems for the tropical climate, rainy, snowy or high wind (cyclonic) regions. The biggest advantage to using this style of roof is its durability.It is designed to resist water infiltration and able to withstand strong wind. rainy and high wind-speed areas.

Feature

LokSeam is a type of standing seam which produces a superior watertight seal and speeds up the installation process. It is installed using hidden clips and fasteners. The clips are secured to the roof deck and in turn, hold the panels in place. The clips allow for full thermal movement of the roofing panels. With this technique, we overcome the disadvantages of 5 rib steel panels: don’t put holes in the panels that are protecting your structure.

LokSeam 470 panel has a width coverage of 470mm with 66mm high ribs including the seam. The minimum roof slope of LokSeam 470 panel is 3%.

Advantages

-

This type of roofing sheet has the highest anti-leak and anti-overflow performance, so it is used in areas with heavy rainfall and high-wind regions. It can protect your building for wind resistance against even hurricane-strength winds.

-

The length of a roofing sheet is up to 120m without joints

-

Resistance to strong winds up to 300km / h

-

Heat expansion does not transfer to purlin: Extra safety factor

-

Anti-leak, anti-gas leak to save energy and operating costs.

Application

Ton Lokseam 470 is one of the strongest and most weather-tight standing seam roof systems available in the industry today. It is suitable for a tropical monsoon climate with lots of rain and storms like in Vietnam. Currently, Lokseam is widely used in pre-engineered steel buildings such as factories, warehouses, showrooms, trade centers … for low-slope roofs.

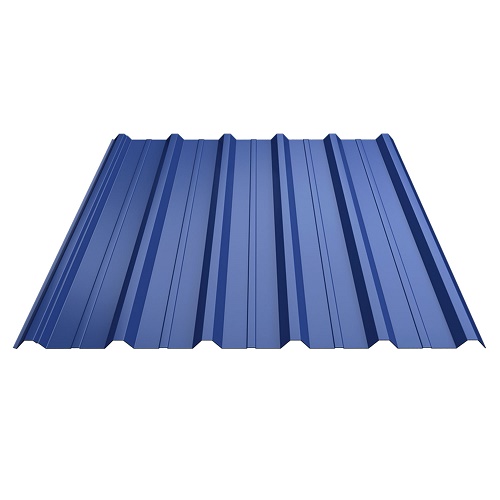

KlipLok 406 steel panel

VIS KlipLok 406 steel panel lasts significantly longer and requires less maintenance, especially when compared to other roofing types. This type of sheeting roof is built to last, so it doesn’t rust and most don’t fade in the sun, either. With flexible variable length, VIS KlipLok is suitable for roofing and cladding of many types of projects.

Feature

KlipLok 406 panel has a width coverage of 406mm with 41mm high ribs. The minimum roof slope is 5%

KlipLok steel panel design holds a fixed clip inside a fold at the top of the panel seam, so the sealant in the cap is in full continuous contact with the top of the panel seam with no interruptions.

Advantages

In Kliplok roofing systems, the panels generally aren’t double pinned, meaning they can expand and contract better. Because it’s a snap-lock system where the metal can move freely with a clip. Moreover, the fasteners are concealed and only exposed at isolated locations. This feature allows for less maintenance.

Because the long panels of metal sheets are continuous, potential weak spots and entry points for leaks can be avoided.

It can protect your building for wind resistance against even hurricane-strength winds.

It can greatly reduce completion time and also offer a higher quality roof system.

Application

KlipLok 406 is suitable for roofs with a slope as low as 7%. This type of panel is also used to erect cladding in both vertical and horizontal direction for pre-engineered steel buildings, industrial buildings.